ACCOMMODATION OF LIFTING MOVEMENTS

To accommodate larger lifting movements, Rattay stainless steel metal hoses are installed in the 180 degree elbow. To calculate the required hose length, proceed as follows:

9.1.1 Installation plan

180° elbow vertical

Movement: vertical

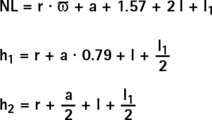

| E | mm | installation distance |

| NL | mm | total length of the metal hose |

| r | mm | installation radius |

| l1 | mm | 5 · DN Reserve for balancing assembly inaccuracies |

| l | mm | length of a sealing part. To calculate NL, h1 and h2 the length of the longest connection parts must be used. |

| a | mm | total travel |

| h1 | mm | maximum height of the 180° elbow |

| h2 | mm | minimum height of the 180° elbow |

Example 1

Example

Rattay stainless steel corrugated hose DN 40 Type HR I/S, on both sides screw connections made of stainless steel, Fig. 114.

Operating data

- Lift vertical a = 300 mm

- Installation radius r = 400 mm (310 mm min.)

Calculation

l = 95 mm

l1 = 5 · 40 = 200 mm

NL = 400 · ![]() +

+ ![]() + 2 · 95 + 200 = 1,796 mm (Order length NL = 1,800 mm)

+ 2 · 95 + 200 = 1,796 mm (Order length NL = 1,800 mm)

h1 = 400 + ![]() + 95 +

+ 95 + ![]() = 745 mm

= 745 mm

h2 = 400 + 95 + ![]() = 595 mm

= 595 mm

9.1.2 Installation plan

180 elbow vertical

Movement: horizontal

| E | mm | installation distance |

| NL | mm | total length of the metal hose |

| r | mm | smallest bending radius for frequent movements |

| l1 | mm | 5 · DN Reserve for balancing assembly inaccuracies |

| l | mm | length of a sealing part. To calculate NL, h1 and h2 the length of the longest connection parts must be used. |

| a | mm | total travel |

| h1 | mm | maximum height of the 180° elbow |

| h2 | mm | minimum height of the 180° elbow |

| DN | mm | nominal width of the metal hose |

Example 2

Example

Rattay stainless steel corrugated hose DN 25 Type HR I/S, on both sides screw connections made of stainless steel, Fig. 107 c.

Operating data

- Lift horizontal a = 250 mm

Calculation

l = 85 mm see dimension table connection parts

r = 205 mm see hose table

l1 = 5 · 25 = 125 mm

NL = 205 · ![]() + 250 · 1.57 + 85 + 125 = 1,331.2 mm (Order length NL = 1,400 mm)

+ 250 · 1.57 + 85 + 125 = 1,331.2 mm (Order length NL = 1,400 mm)

h1 = 250 + 250 · 0.75 + 85 + ![]() = 550 mm

= 550 mm

h2 = 205 + ![]() + 85 +

+ 85 + ![]() = 447.5 mm

= 447.5 mm

9.1.3 Installation plan

180° elbow vertical

Movement: horizontal and vertical

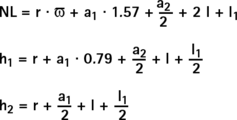

| E | mm | installation distance |

| NL | mm | total length of the metal hose |

| r | mm | smallest bending radius for frequent movements |

| l1 | mm | 5 · DN Reserve for balancing assembly inaccuracies |

| l | mm | length of a sealing part. To calculate NL, h1 and h2 the length of the longest connection parts must be used. |

| a1 | mm | total travel horizontal |

| a2 | mm | total travel vertical |

| h1 | mm | maximum height of the 180° elbow |

| h2 | mm | minimum height of the 180° elbow |

Example 3

Example

Rattay stainless steel corrugated hose DN 32 Type HR I/S, on the one side a screw connection made of stainless steel, Fig. 107 c, on the other a side screw connection made of stainless steel, Fig. 107 b.

Operating data

- Lift horizontal a1 = 150 mm

- Lift horizontal a2 = 250 mm

Calculation

l = Imax = 95 mm see dimension table connection parts (for AS 51, AS 55 only 84 mm long)

r = 260 mm see hose table

l1 = 5 · 32 = 160 mm

NL = 260 · ![]() + 150 · 1.57 +

+ 150 · 1.57 + ![]() 2 · 95 +160 = 1,526.9 mm (Order length NL = 1,600 mm)

2 · 95 +160 = 1,526.9 mm (Order length NL = 1,600 mm)

h1 = 260 + 150 · 0.79 + ![]() + 95 +

+ 95 + ![]() = 678.5 mm

= 678.5 mm

h2 = 260 + ![]() + 95 +

+ 95 + ![]() = 510 mm

= 510 mm

9.1.4 Installation plan

180° elbow horizontal

Movement: horizontal

If installed horizontally, a support for the metal hose, e.g. a supporting mould or roller, must be attached.

| E | mm | installation distance |

| NL | mm | total length of the metal hose |

| r | mm | installation radius |

| l1 | mm | 5 · DN Reserve for balancing assembly inaccuracies |

| l | mm | length of a sealing part. To calculate NL, h1 and h2 the length of the longest connection parts must be used. |

| a | mm | total travel |

| h1 | mm | maximum height of the 180° elbow |

| h2 | mm | height of the 180° elbow |

Example 4

Example

Rattay stainless steel corrugated hose DN 40 Type HR I/S, on both sides screw connections made of stainless steel, Fig. 107 c.

Operating data

- Lift horizontal a = 200 mm

- Bending radius r = 350 mm (310 mm min.)

Calculation:

l = 98 mm see dimension table connection parts

l1 = 5 · 40 = 200 mm

NL = 350 · ![]() +

+ ![]() + 2 · 98 + 200 = 1,595 mm (Order length NL = 1,600 mm)

+ 2 · 98 + 200 = 1,595 mm (Order length NL = 1,600 mm)

h1 = 350 + ![]() + 98 +

+ 98 + ![]() = 648 mm

= 648 mm

h2 = 350 + 98 + ![]() = 548 mm

= 548 mm